When it comes to industrial facilities that deal with hazardous materials or volatile gases, safety is of the utmost importance. One of the main concerns in these environments is the risk of explosions or fires caused by electrical equipment. This is where explosion proof light fixtures come in.

What is an Explosion Proof Light Fixture?

An explosion proof light fixture is specially designed to prevent the ignition of flammable gases or dust particles that may be present in the air. These fixtures are constructed in a way that minimizes the likelihood of sparks or arcs being generated by electrical components. In the event of an explosion or fire, these fixtures are able to contain the blast and prevent it from spreading throughout the facility.

Why Use Explosion Proof Light Fixtures?

There are many reasons why explosion proof light fixtures are essential in hazardous environments. One of the main reasons is worker safety. With the risk of explosions and fires, it's crucial to have lighting that won't ignite flammable substances in the air. This not only protects workers, but can also prevent costly damage to equipment and facilities.

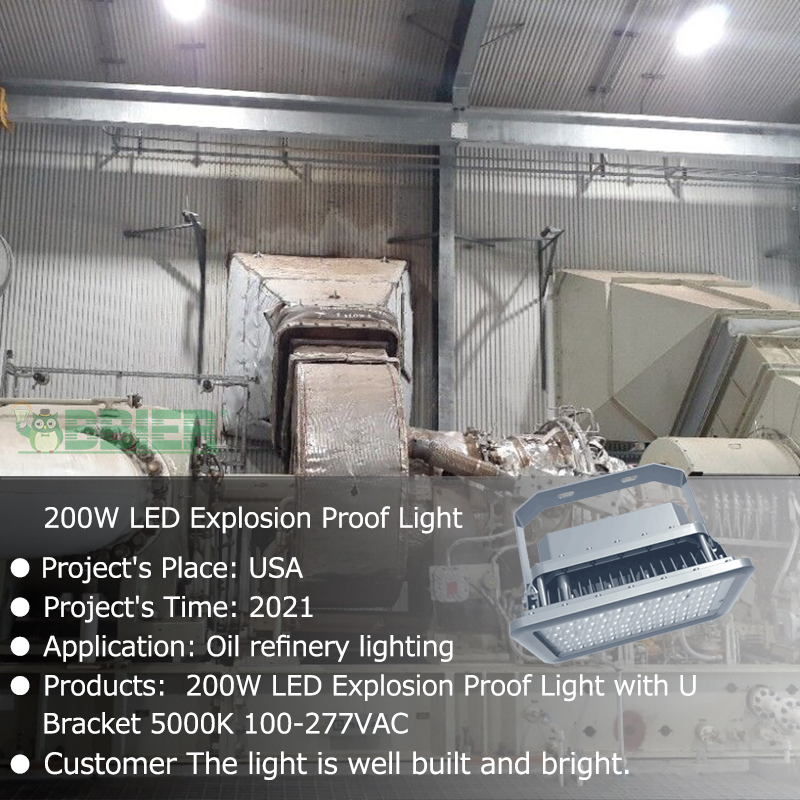

Another reason to use explosion proof light fixtures is to comply with regulations. Many industrial facilities are required by law to use explosion proof lighting in certain hazardous areas. This includes areas where flammable gases or dusts are present, such as petroleum refineries, chemical plants, and grain elevators.

Features of Explosion Proof Light Fixtures

Explosion proof light fixtures come in a variety of styles and sizes to suit different environments and applications. Some common features of these fixtures include:

- Class and division ratings: Explosion proof light fixtures are classified based on their suitability for different hazardous environments. The most common classifications are Class I (for flammable gases and vapors), Class II (for combustible dusts), and Class III (for ignitable fibers and flyings). Each class is further divided into divisions based on the likelihood of a hazard occurring.

- Impact resistance: Explosion proof light fixtures are often designed to withstand impacts from objects or debris. This is important in environments where equipment may be dropped, or where machinery may create vibrations.

- Corrosion resistance: In environments where corrosive substances are present, such as chemical processing plants or marine applications, explosion proof light fixtures need to be able to resist rust and degradation.

- Energy efficiency: Many explosion proof light fixtures use LED technology to provide bright, long-lasting light while consuming minimal electricity. This can save on energy costs and help reduce the facility's carbon footprint.

Choosing the Right Explosion Proof Light Fixture

When choosing an explosion proof light fixture, it's important to consider the specific hazards and requirements of your facility. Factors to consider include the type of classified environment, the level of impact and corrosion resistance needed, and the desired level of energy efficiency.

It's also important to choose a reputable manufacturer that can provide UL-certified fixtures that meet strict safety standards. The Magnalight explosion proof LED light fixture, for example, offers a Class 1 Division 1 & 2 and Class 2 Division 1 & 2 explosion proof rating and is constructed of copper-free aluminum alloy for corrosion resistance. Its four LED lamps are enclosed within impact and heat-resistant Pyrex tubes for added safety.

Conclusion

Explosion proof light fixtures are an essential safety feature in industrial facilities where hazardous materials are present. These fixtures are designed to prevent the ignition of flammable substances, contain blasts and prevent fires from spreading. When choosing an explosion proof light fixture, it's important to consider the specific hazards and requirements of your facility, and to choose a UL-certified fixture from a reputable manufacturer like Magnalight.